NEC and WingArc1st Strengthen Business Collaboration in Data Utilization to Improve Factory Activities in Manufacturing

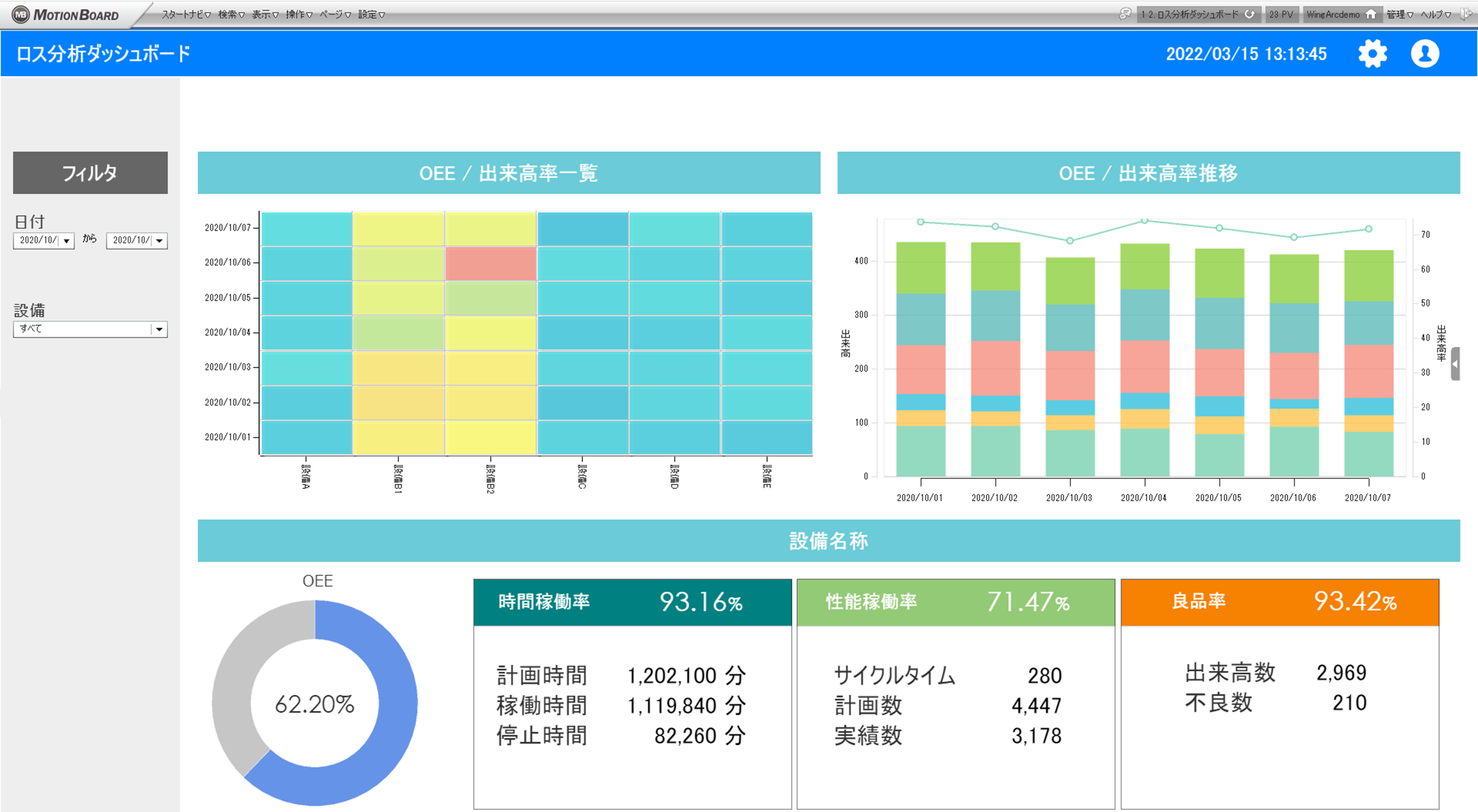

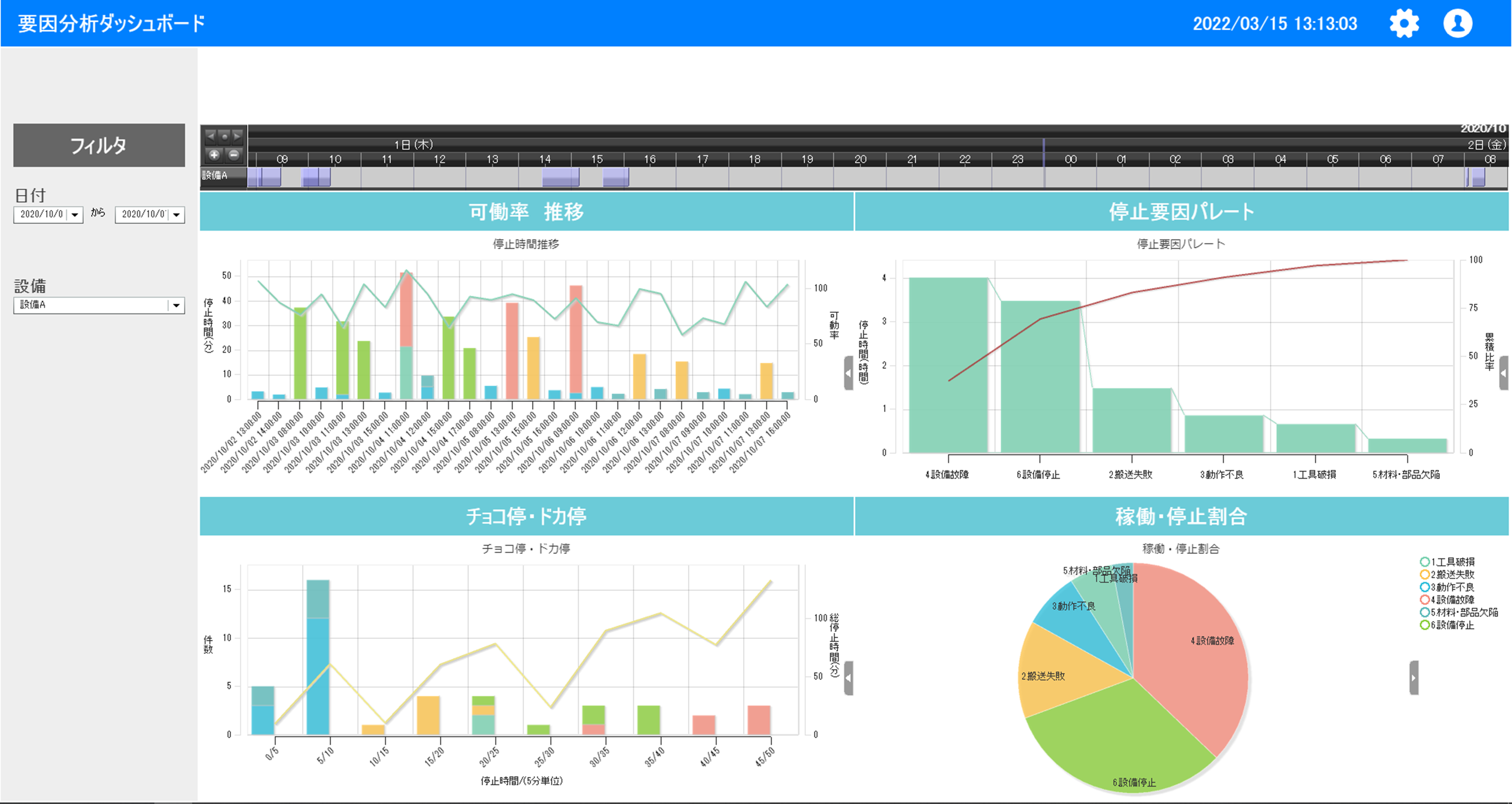

MotionBoard BI Dashboard integrated with the NEC Industrial IoT Platform, IoT Platform for the Manufacturing Industry

WingArc1st Inc.

NEC Corporation

NEC Corporation (NEC) and WingArc1st (WingArc) have agreed to collaborate in data utilization to improve factory activities in the manufacturing industry. Specifically, they will integrate the "NEC Industrial IoT Platform" *1 and WingArc's BI Dashboard, "MotionBoard" *2 into a single platform to shorten the cycle of improvement activities using data from manufacturing factories and promote data-driven improvement activities on the customers' side.

As the first step in the collaboration, they will support customers' data analysis and effectiveness verification by leveraging both companies' know-how in the manufacturing area through NEC's consulting service "NEC Monozukuri DX Kaizen Approach".

In recent years, the environment surrounding the manufacturing industry has become increasingly complex, with the acceleration of DX, as well as the ongoing response to increasing natural disasters and decarbonization. Under these circumstances, there is a need to improve the ability to respond to fluctuations and enhance the ability to change by utilizing data to understand the situation in real time and continuously keep an optimal state. It is often the case that even when data on equipment and manufacturing processes is collected at the facility, the collected data is not being used effectively and efficiently. Typical reasons include a "lack of understanding of analysis methods," "data not being relevant," and "lack of skilled professionals to complete the analysis".

Outline of Strengthening Business Collaboration

Enhancement of "NEC Monozukuri DX Kaizen Approach," a consulting service to improve factory activities

"NEC Monozukuri DX Kaizen Approach" is a consulting service that digitizes the "Takumi's Kaizen Approach" developed through NEC's production innovation activities over a quarter of a century. It analyzes and verifies the effectiveness of the approach by combining manual work data with site data already obtained by the customer.

Specifically, the customer's facility data and manual work data acquired from "NEC Manual Work Navigation" *3 and "Video Management System Appliance Server" *4 are stored in the "NEC Industrial IoT Platform", and data analysis and effectiveness verification are performed to clarify the direction of improvement.

By integrating this service with MotionBoard, which has been adopted by many customers in the manufacturing industry and holds the top share of domestic BI dashboards, it is possible to express data specialized for the manufacturing industry, visualize, and analyze more advanced data on each facility and personnel at the facilities, and make quick improvements. There are also plans to enhance MotionBoard to work with video in the future.

NEC and WingArc will contribute to customers' data-driven improvement efforts by integrating traditional improvement methods and digital data utilization according to the customers' manufacturing style and production characteristics.

Future Business Collaboration

WingArc will continue to support the manufacturing industry by strengthening its functions in the area of data utilization, as well as structural reform of the manufacturing industry using digital technology.

NEC will continue to strengthen its collaboration with WingArc to enhance cooperation with partner companies in the Smart Factory and Manufacturing DX businesses. Specifically, NEC will enhance the analysis screen templates for solving manufacturing issues by leveraging its experience and the results of the "NEC Monozukuri DX Kaizen Approach".

NEC Corporation (Head office: Minato-ku, Tokyo, Japan); President and CEO: Takayuki Morita

*1 A platform that grows with the constantly changing manufacturing environment to realize next-generation manufacturing innovation. It collects and accumulates manufacturing site information via IoT, and processes and provides data in a form that is easy for companies to utilize.

https://jpn.nec.com/manufacture/monozukuri/iot/platform.html#anc-link02 (Japanese)

*2 A dashboard that transforms data from manufacturing facilities into valuable information, enables real-time status monitoring with intuitive operability, and is also compatible with IoT applications. With an extensive track record of more than 2,000 companies across a wide variety of industries, including manufacturing, it is a solution that can contribute to solving customers' issues.

https://www.wingarc.com/product/motionboard/index.html (Japanese)

https://www.wingarc.com/en/product/motionboard/index.html (English)

*3 A solution to support digitization and improvement of work quality by digitizing manual work in the factory.

https://jpn.nec.com/manufacture/monozukuri/iot/solution/navigation.html (Japanese)

*4 24-hour video management system for checking access to offices and facilities and managing factory lines.

https://jpn.nec.com/pcserver/appliance/vms/product.html (Japanese)

Contact on Products and Services:

WingArc1st Inc.

Roppongi Grand Tower, 3-2-1 Roppongi, Minato-ku, Tokyo106-0032, Japan

TEL : 81-3-5962-7300

FAX : 81-3-5962-7301

E-mail :

Inquiry on This Press Release:

WingArc1st Inc. PR team: Yamamoto, Nakatani, Iisaka, Furusho

TEL : +81 90 5391 1510 (Yamamoto) , +81 80 3006 2396 (Furusho)

E-mail :

*Company names and products names enlisted in this Press Release are trademarks or registered trademarks of each company.